In the world of meat processing, safety is paramount.

Ensuring the well-being of our employees and maintaining the highest standards of hygiene is not only a moral responsibility but also a legal obligation.

At Jarvis Products Kenya, as the leading manufacturer and supplier of slaughtering and meat processing equipment, we understand the critical role that Personal Protection Equipment (PPE) plays in safeguarding the health and safety of workers in our industry.

In this blog post, we’ll delve into the significance of PPE in meat processing and highlight the essential types of equipment to consider.

Meat processing facilities can be challenging environments to work in.

From the sharp tools and machinery to the potential exposure to various hazards like bacteria, chemicals, and extreme temperatures, the risks are manifold.

Therefore, providing adequate protection for our employees is not just a matter of compliance; it’s about creating a safe and efficient workplace.

Cut-Resistant Gloves:

In a meat processing plant, workers are constantly handling sharp knives, saws, and other cutting tools.

Cut-resistant gloves are a crucial piece of PPE that can significantly reduce the risk of injuries.

These gloves are designed to protect against cuts and punctures, providing a layer of defense for workers’ hands.

Aprons and Full-Body Suits:

Protecting the body from contaminants and chemicals is vital in meat processing.

Disposable aprons and full-body suits are worn to prevent direct contact with potentially harmful substances.

These should be made of materials that are resistant to moisture and chemicals.

Respiratory Protection:

Meat processing can produce airborne particles, including dust and fumes, which can be harmful when inhaled.

Proper respiratory protection, such as masks or respirators, is necessary to ensure that workers breathe clean air and reduce their risk of respiratory issues.

Hearing Protection:

Meat processing machinery can be loud, leading to potential hearing damage over time. Earplugs or earmuffs are essential to protect workers’ hearing.

Head Protection:

Hard hats or bump caps should be worn to protect against head injuries from falling objects or collisions with equipment.

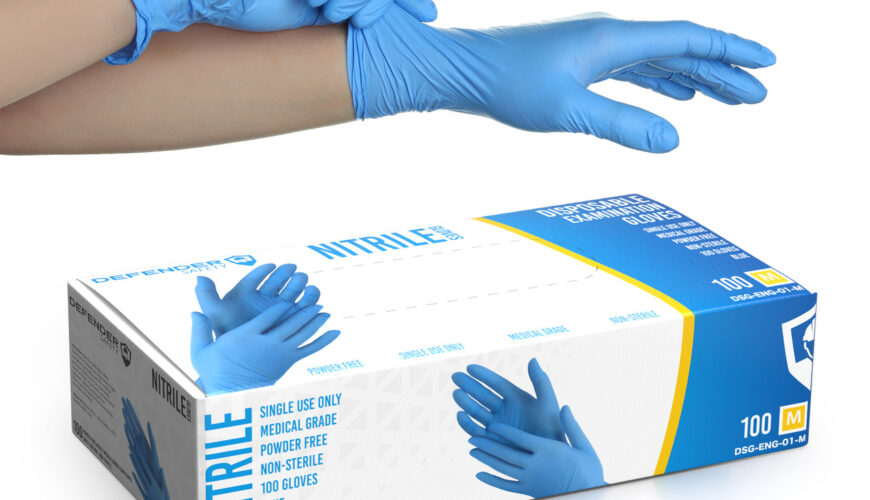

Disposable Gloves:

To maintain hygiene, it’s essential to use disposable gloves when handling raw meat products.

These gloves should be changed regularly to prevent cross-contamination.

Safety Goggles and Face Shields:

Eye injuries are all too common in the meat processing industry due to flying debris, chemicals, and splashes of blood or other fluids.

Safety goggles and face shields are essential for safeguarding the eyes and face, preventing serious injuries.

Footwear:

The right footwear is essential in a meat processing plant.

Slip-resistant, waterproof boots that are easy to clean are crucial to prevent slips and falls, which are common accidents in such environments.

In Conclusion:

In the meat processing industry, where safety and hygiene are paramount, Personal Protection Equipment (PPE) is not an option but a necessity.

As the leading manufacturer and supplier of meat processing equipment, Jarvis Products Kenya is committed to promoting safe working conditions for all employees in the meat processing sector.

By providing the right PPE and ensuring its proper use, we can minimize the risk of accidents, protect the health of our workforce, and maintain the highest quality standards in meat processing.

Remember, investing in PPE is an investment in your employees’ safety and the overall success of your meat processing business.

Prioritize safety, and together we can create a safer, more efficient meat processing industry for everyone involved.

meat industry served differently

Our meat processing bandsaw blades, made from high-quality stainless steel, offer durability, efficient cutting, and sanitation for optimal meat processing performance. To shop this and more click shop button below:

At Unbeatable Prices