Steam Vacuum System

A meat processing Steam Vacuum System is a specialized cleaning tool designed specifically for the meat processing industry. It combines the power of steam and vacuum technology to provide efficient and hygienic cleaning of meat processing equipment, surfaces, and areas.

The Steam Vacuum System is typically designed to handle the unique cleaning requirements of meat processing facilities. It consists of a compact and robust unit that generates high-temperature steam and incorporates a powerful vacuum system.

The steam component of the system produces hot, pressurized steam, which effectively sanitizes and loosens dirt, grease, and other residues commonly found in meat processing environments. The steam penetrates into hard-to-reach areas, ensuring thorough cleaning and disinfection.

The vacuum component of the system simultaneously extracts the steam, dissolved contaminants, and moisture. It helps to remove debris, liquids, and residual cleaning agents, leaving the surfaces clean, dry, and ready for use.

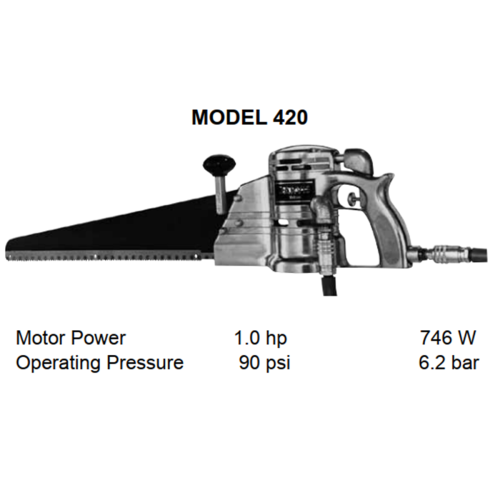

The Steam Vacuum System is equipped with various attachments and accessories tailored for meat processing applications. These may include specialized steam nozzles, brushes, crevice tools, and squeegees that facilitate efficient cleaning of different types of equipment, such as slicers, grinders, mixers, conveyors, and workstations.

The system is designed with operator convenience and safety in mind, featuring user-friendly controls, ergonomic handles, and integrated safety features. It may also incorporate features like adjustable steam pressure and temperature settings to adapt to different cleaning tasks and surfaces.

Using a meat processing Steam Vacuum System offers several advantages. It helps to maintain strict hygiene standards, ensuring the removal of bacteria, pathogens, and contaminants that can compromise food safety. It can also reduce the need for manual scrubbing and chemical cleaning agents, promoting a more environmentally friendly and sustainable cleaning process.

Specific features, capabilities, and designs of meat processing Steam Vacuum Systems may vary among manufacturers. It is recommended to consult with suppliers or industry experts to obtain accurate information on the specific system that suits your meat processing facility’s cleaning needs.

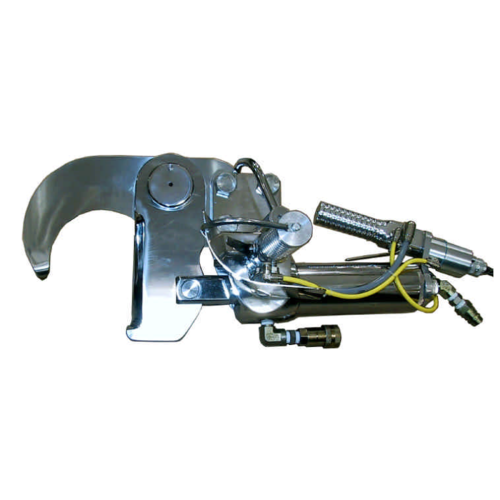

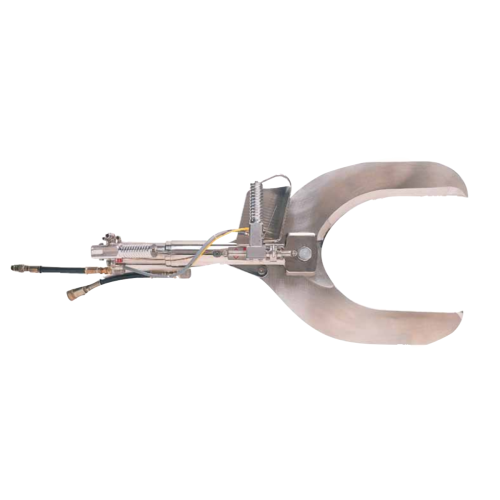

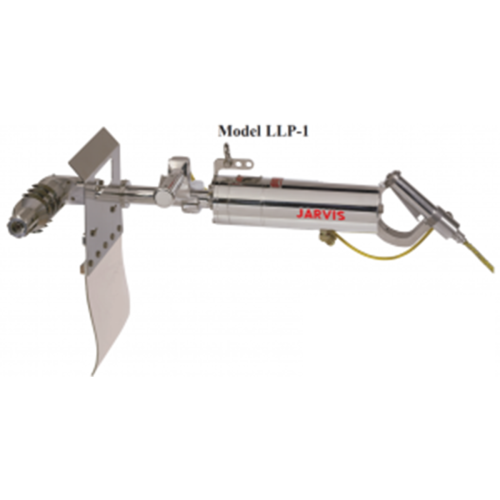

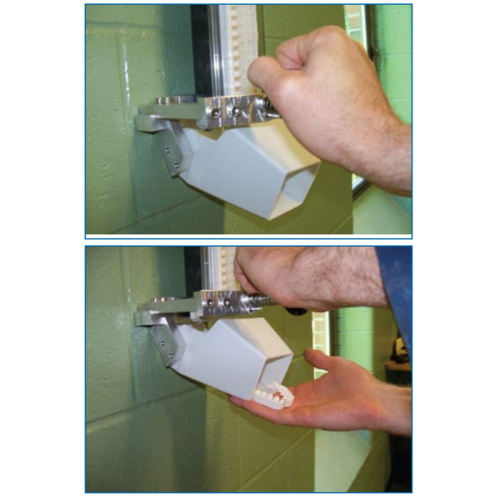

• The CV-1 is specifically designed for pathogen reduction and the spinal cord removal on the carcasses of beef, pork and lamb.

• Increases shelf-life by reducing the amount of bacteria found on the carcass.

• Increases yields – less trimming required.

• Lightweight handpiece for optimum operator comfort.

• High vacuum – for fast removal of contamination and spinal cords.

• Different nozzles for specific applications.

• All stainless construction for maximum hygiene.

• Meets national and international requirements for hygiene and safety.

[wpdm_package id=’12410′]