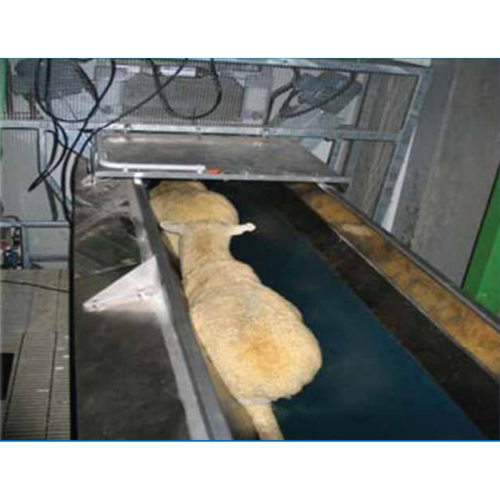

Belt-Type Vacuum Packaging

Belt-type vacuum packaging is a method used in meat processing and packaging to remove air from the packaging material and create a vacuum seal around the product. It is commonly used for vacuum sealing meat cuts, processed meats, and other perishable food items. Here are some key features and components of a typical belt-type vacuum packaging system:

- Conveyor Belt: The system consists of a conveyor belt that moves the products through the packaging process. The conveyor belt allows for continuous and automated packaging, ensuring efficiency and productivity.

- Vacuum Chamber: The vacuum chamber is a key component of the system where the packaging process takes place. The chamber is designed to accommodate the product being packaged and create a vacuum environment.

- Sealing Mechanism: The belt-type vacuum packaging system is equipped with a sealing mechanism, typically using heat sealing technology, to create a tight and secure seal around the packaging material. This ensures that the vacuum is maintained throughout the shelf life of the product.

- Vacuum Pump: A vacuum pump is used to remove air from the packaging material and the vacuum chamber. The pump creates suction that pulls out the air and creates the desired vacuum level inside the packaging.

- Control Panel: The system features a control panel that allows operators to set and adjust various parameters, such as vacuum level, sealing time, conveyor speed, and other packaging settings. This provides control and flexibility in achieving the desired packaging results.

- Sensors and Safety Features: Belt-type vacuum packaging systems are equipped with sensors and safety features to ensure proper operation and prevent any hazards. These may include sensors for detecting packaging material and product placement, emergency stop buttons, and safety interlocks.

- Versatility and Customization: The system offers versatility in packaging different types of meat products, accommodating various sizes, shapes, and weights. It can be customized to meet specific packaging requirements and can handle a wide range of packaging materials, such as vacuum bags or pouches.

- Durability and Hygiene: Belt-type vacuum packaging systems are built with durable materials, such as stainless steel, to withstand the demands of continuous operation. They are designed for easy cleaning and maintenance, adhering to high hygiene standards in food processing and packaging.

Belt-type vacuum packaging systems are widely used in meat processing facilities, butcher shops, and other food manufacturing settings. They provide an effective way to preserve the quality and extend the shelf life of meat products by removing air and creating a vacuum seal. By minimizing exposure to oxygen, these systems help to prevent spoilage, maintain freshness, and enhance food safety.

Category: Packaging Equipment

Tags: humane, stun