Beef Dehorner

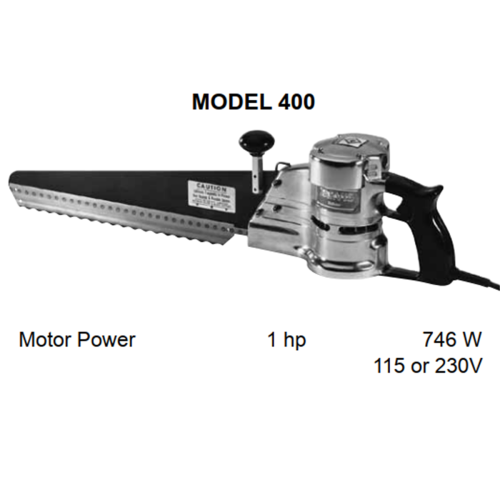

The Jarvis Beef Dehorner is a specialized tool designed to safely and efficiently remove the horns of cattle. Horns on cattle can cause injury to both animals and handlers, and can also damage equipment and facilities. Dehorning is a common practice in the beef industry, and the Jarvis Beef Dehorner is a tool that has been designed specifically to make this process easier and safer.

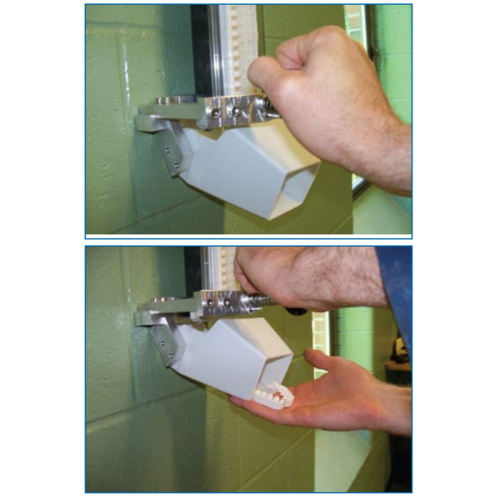

The dehorner is powered by electricity and features a heating element that quickly heats up to the optimal temperature for dehorning. The operator simply places the heated element over the horn and applies pressure until the horn is removed. The process is quick and efficient, and the dehorner is designed with safety in mind. The tool features a heat-resistant handle to protect the operator’s hand, and a safety guard to prevent accidental contact with the heating element.

The Jarvis Beef Dehorner is also designed with hygiene in mind, with easy-to-clean surfaces and materials that prevent bacterial growth and contamination. It is easy to disassemble and reassemble for cleaning, ensuring optimal performance and safety.

Using the Jarvis Beef Dehorner in beef processing facilities improves safety and efficiency, reducing the risk of injury to both animals and handlers. It also improves the quality of the beef products, as dehorned cattle are less likely to damage equipment and facilities, and are therefore easier to handle and process.

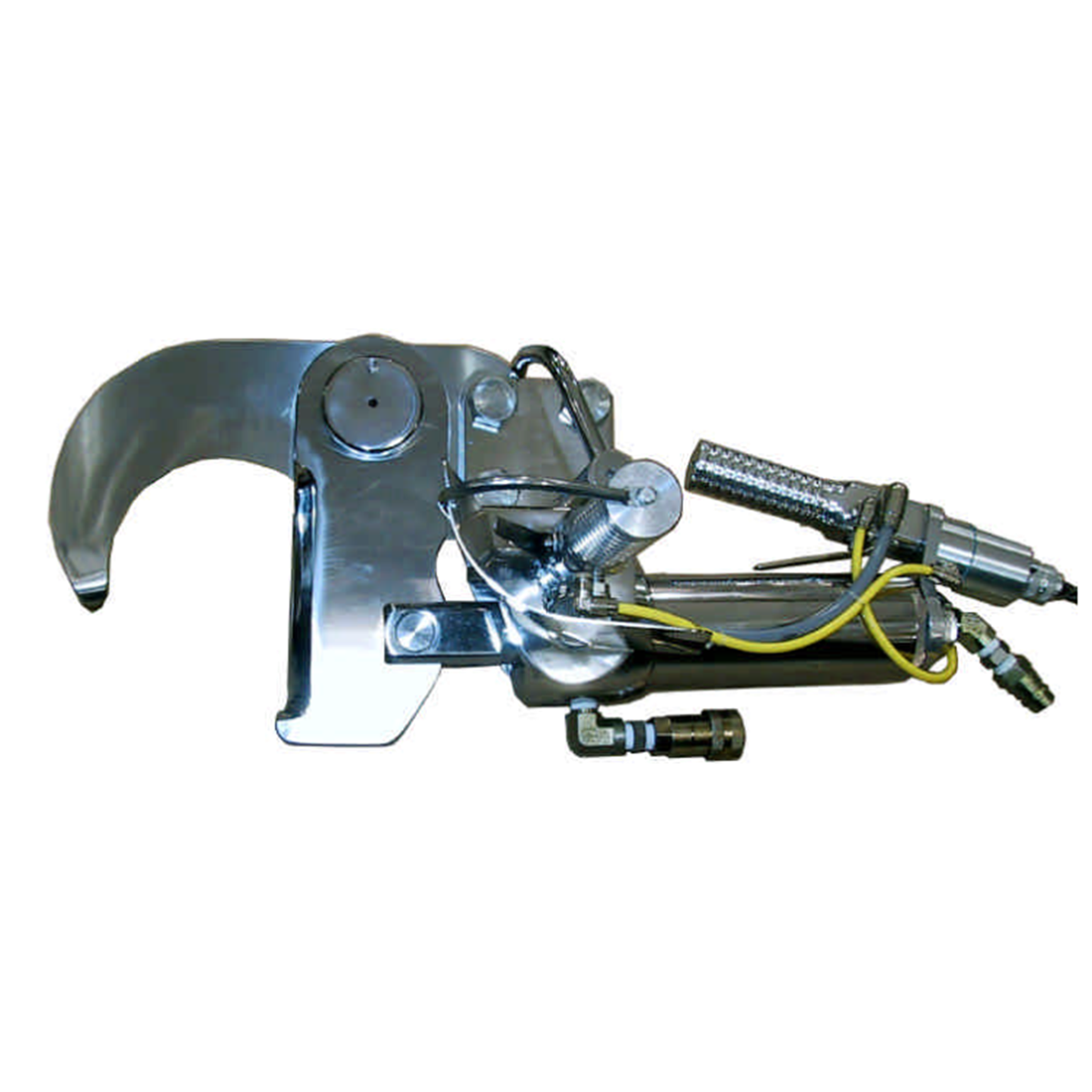

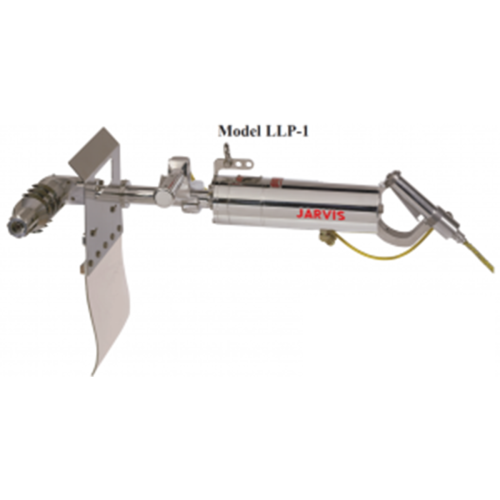

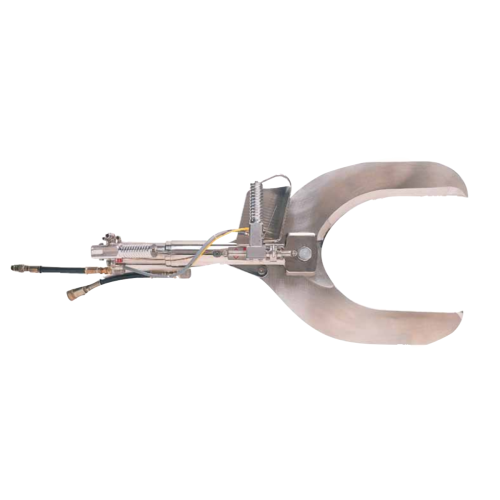

· For beef horns that are not accessible with guillotine type dehorners.

· For front and hind beef hock cutting through the bone or joint.

· With a 2.1 second cutting cycle, the 50D-1 is a high production, high performance tool – used for the most demanding applications, especially where one operator cuts both horns and front hocks.

· Best possible hygiene with updated, virtually all stainless steel construction – minimal corrosion problems.

· Robust construction, including ground solid stainless steel blades, for long troublefree life.

· Anti-tie down controls for operator safety.

· Meets national and international requirements for safety and hygiene